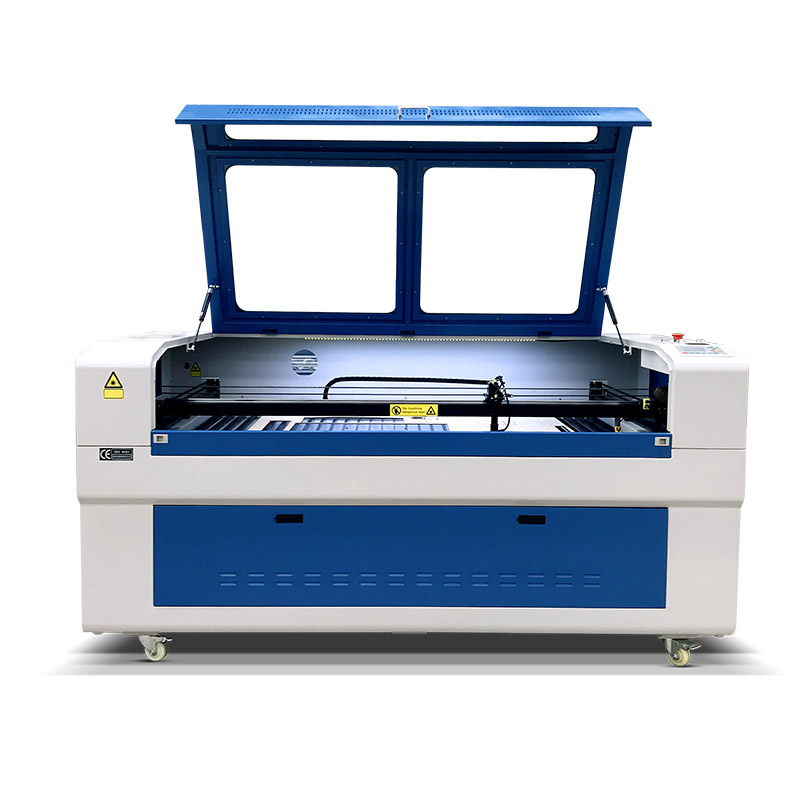

Quality Inspection For Lightweld 1500 Laser - Handheld fiber laser welding machine for aluminum stainless steel iron – Hoseng

Quality Inspection For Lightweld 1500 Laser - Handheld fiber laser welding machine for aluminum stainless steel iron – Hoseng Detail:

The welding speed is 2-10 times faster than the traditional welding. One machine can save at least 2 welders a year.

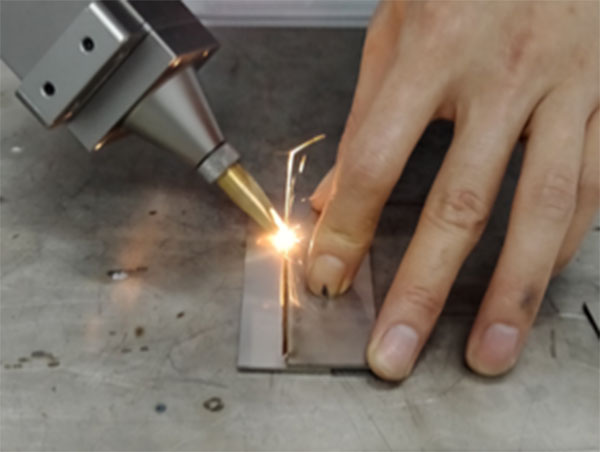

Laser welding

Traditional welding

► The operation is simple, and it is possible to get on the job without a job certificate, and the beautiful product can be welded without the teacher.

Fillet welding, vertical welding

Stitching welding

Overlay welding

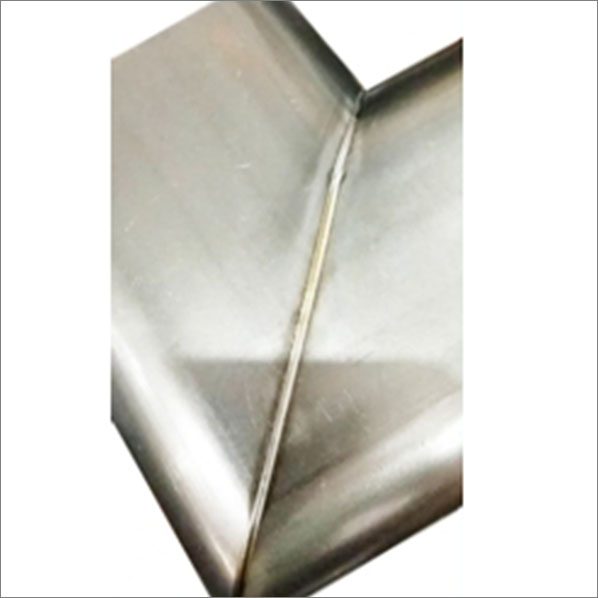

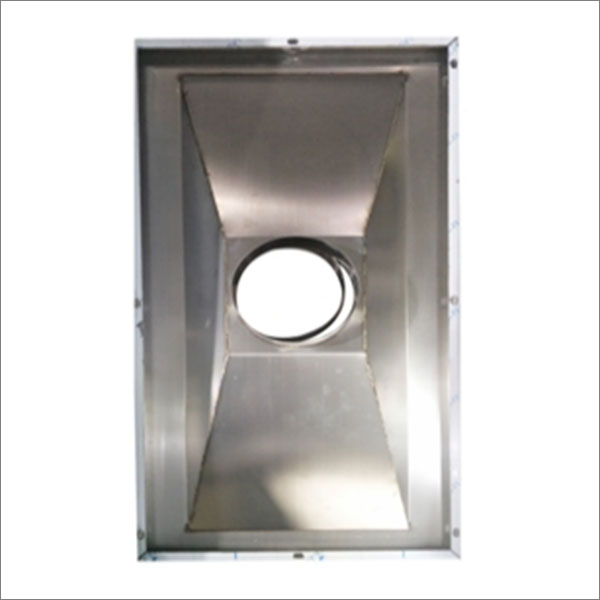

The weld seam is smooth and beautiful, reducing the subsequent grinding process, saving time and cost.

No welding scar

Beautiful weld

No deformation of the workpiece

The self-developed Wobble welding head compensates for the disadvantage of the laser welding small spot, expands the tolerance range of the machined parts and the weld width, and obtains better weld formation.

The welding workpiece has no deformation, no welding scar, and the welding is firm.

Laser welding has less consumables and long life.

Safer and more environmentally friendly.

Product detail pictures:

Related Product Guide:

Our company sticks into the basic principle of "Quality is definitely the life of the business, and status may be the soul of it" for Quality Inspection For Lightweld 1500 Laser - Handheld fiber laser welding machine for aluminum stainless steel iron – Hoseng , The product will supply to all over the world, such as: European, Angola, Florence, We confirm to public, cooperation, win-win situation as our principle, adhere to the philosophy of make a living by quality, keep developing by honesty , sincerely hope to build up a good relationship with more and more customers and friends, to achieve a win-win situation and common prosperity.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.