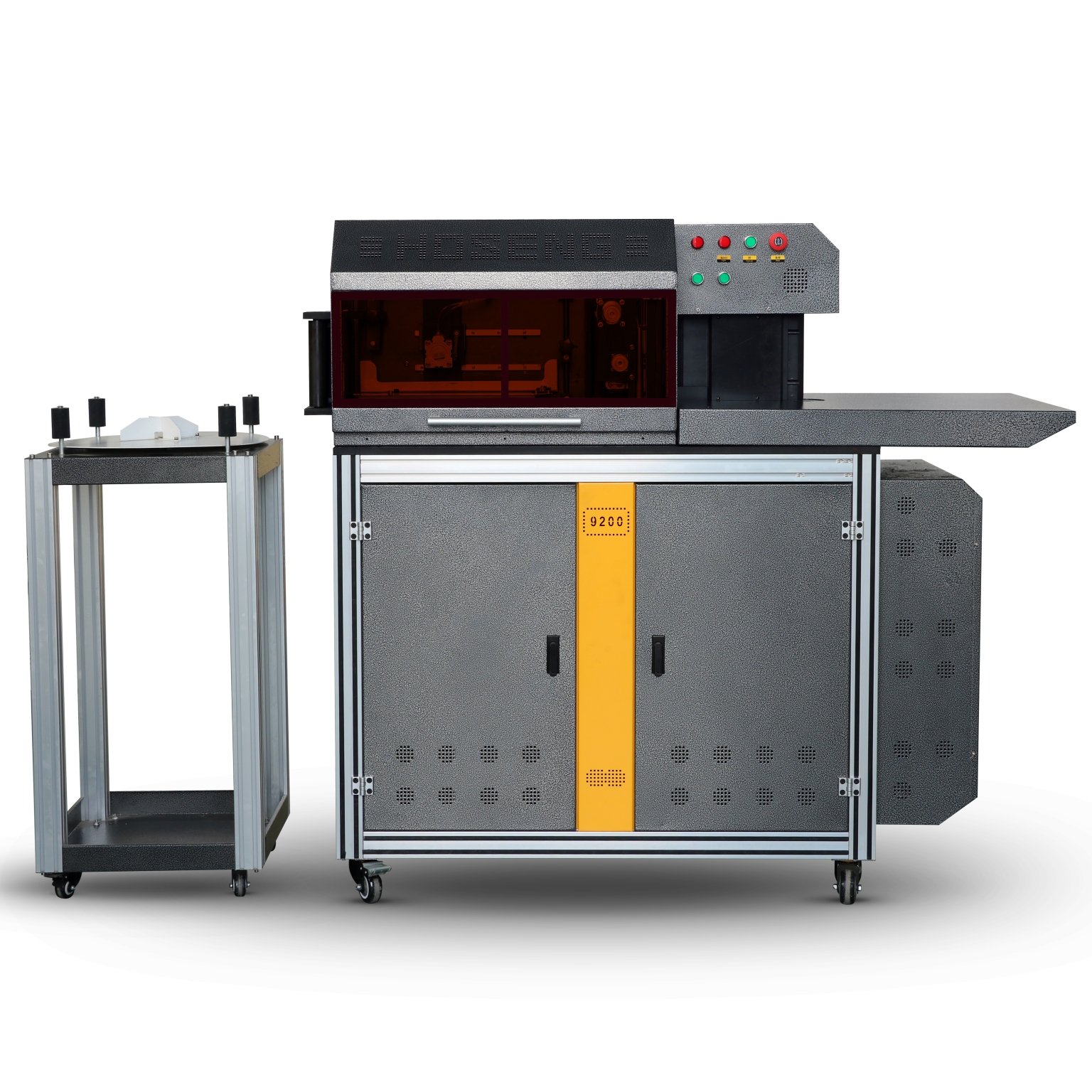

HS-9200 Super Letter Bending Machine

stainless steel, fine light words, words without side punching.

1. Feeding section, manipulator clamping alternating feeding way.

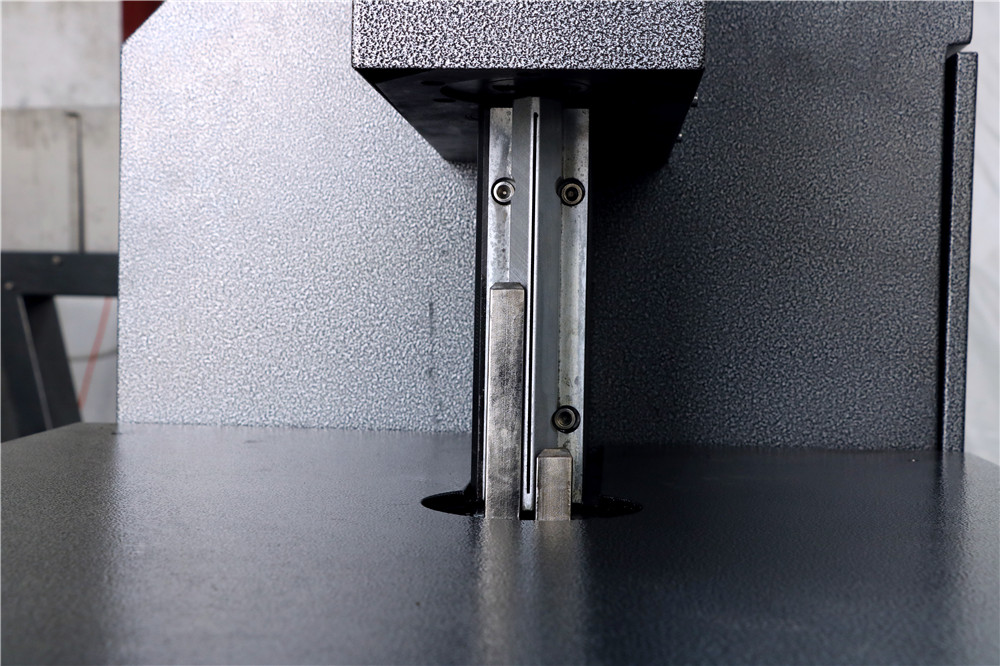

2. Sloting section, equipped with a key switch type double cutting system.

3. Bending parts, high-speed expansion shaft bending, curved shape degree can reach 90%.

4. Feeding closed-loop control, to interact with the encoder testing institutions, feeding error compensation.

5. Intelligent shift, the software automatically generate corresponding to cooperate the contour offset mode.

6. Cutting tool compensation, the software will automatically perfect coordination of numerical calculation and cutting panel, without user adjust the original file.

| Operating principle | Automatic feeding, slotting and bending |

| Available Material | Aluminum profiles, stainless steel, white iron, flat aluminium |

| Bending Radius | ≥5mm |

| Feeding width | 20mm-200mm |

| Feeding Thickness | 0.4-1.5mm |

| Power | ≤3.5KW |

| Machine size | 2250mm×880mm×1380mm |

| Machine weight | 420kg |

| Voltage | 220V |

| Working air pressure | 0.6Mpa |

The stainless steel slotting used the imported plane cutter from Japan. It has low cutting sound, wear-resistant blade, large angle of folding, not easy to break and easy to change.

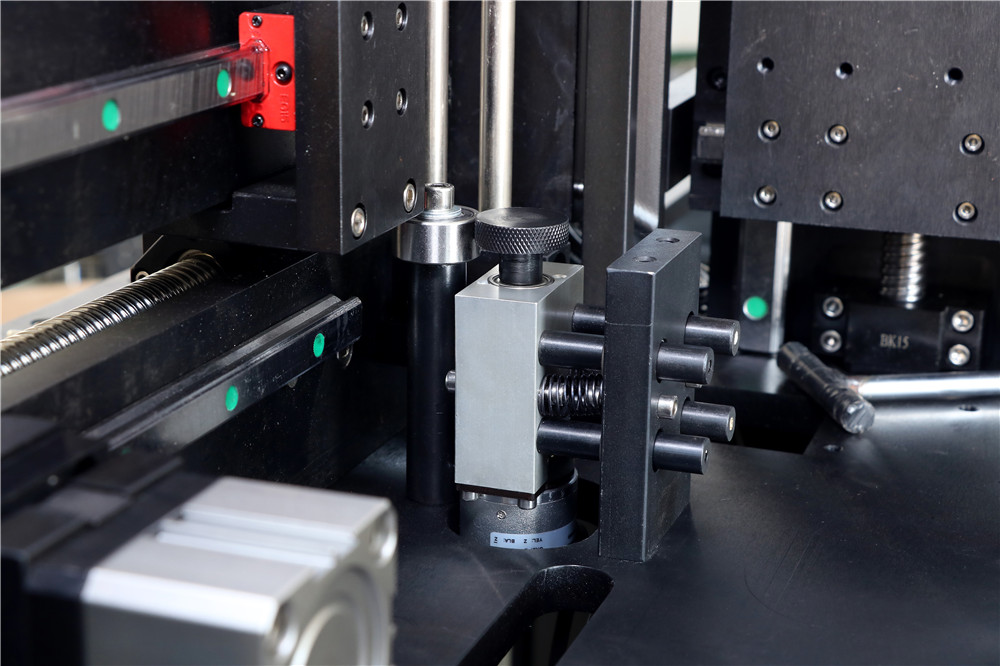

The high quality encoder used in this machine has high reliability, long life and strong anti-interference performance. With the high-speed precision motor, its high-precision performance makes the feeding control more accurate.

The control card and software is original leetro control system, easy to study and operate, ensure the machine calculating size with zero error. The control card running stable, with strong anti-interference ability.

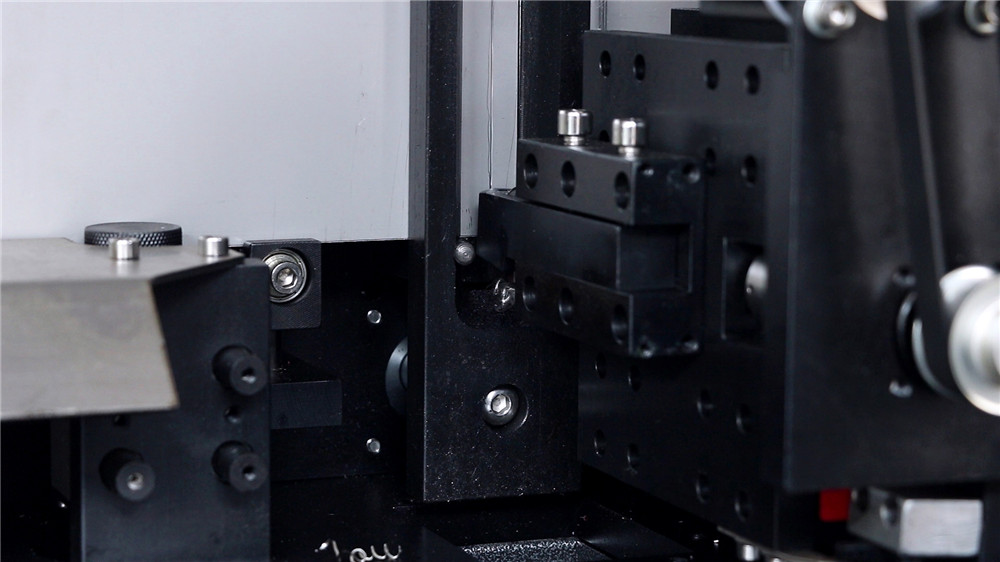

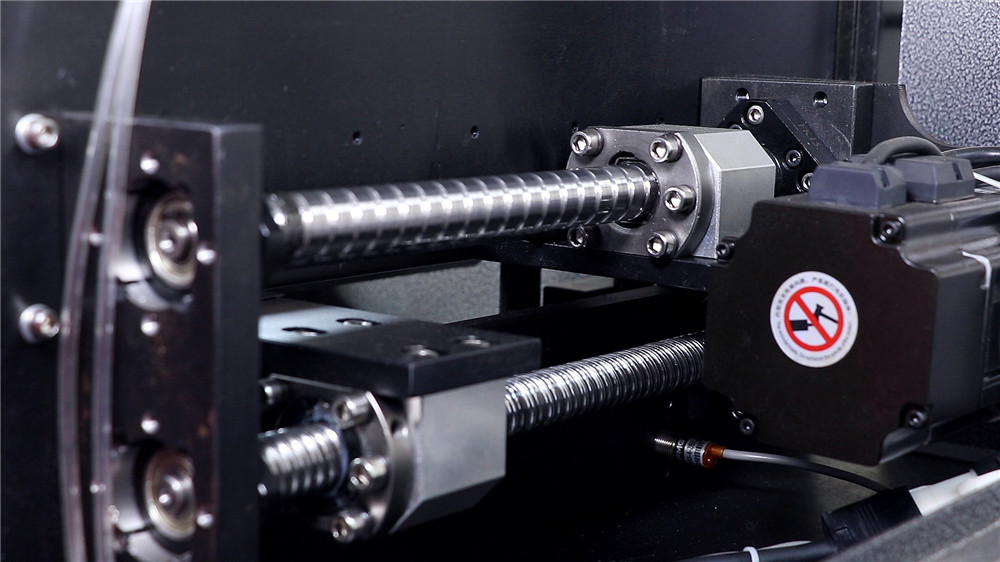

The unique depth adjusting system can automatically adjust the groove depth by modifying the software parameters, and can control the front and back adjustments separately. The motion part adopts screw rod, square rail and slider, which has high precision and good stability.

Alternating feed clamping mechanism, accurate feeding, no indentation on the material surface.

The double ball screw of feeding design ensure the feeding speed and precision as well as stability.

The bending system uses a high-precision servo acceleration and deceleration system, which effectively solves the phenomenon of stainless steel bending and not moving.