HS-5150 Aluminum Letter Bending Machine

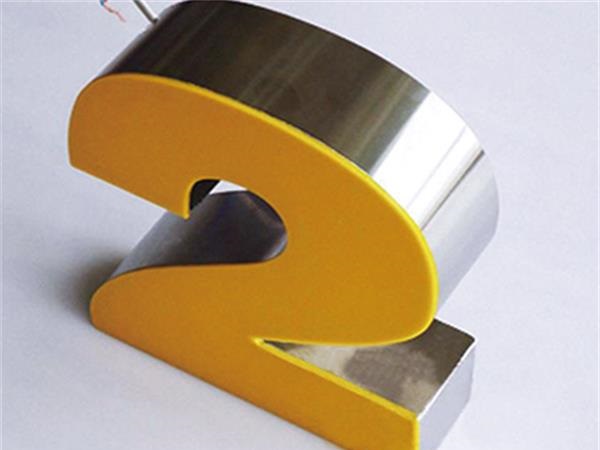

Aluminum channel letter, Trimless channel letter, Aluminum profile channel letter, Liquid acrylic channel letter, Aluminum epoxy channel letter.

1. Automatic computer adjusting system, no need to adjust the slotting depth by hand.

2. Fast bending speed,one time forming,big curve arc is flapped,small curve arc is squeezed.

3. Material width is 30-140mm, thickness is 0.4-1.2mm.

4. Low power consumption, the using power less than 1500W.

5. Can read various vector files in DXF, AI, PLT format, matching with engraving files.

6. Double side slotting,the bending angle of flat sheet is from -180° to 170°.

7. Adopt high quality encoder, high reliability, long lifetime and strong anti-interference performance.

8. Special parameter requirement can be customized.

| Applicable Material | Flat aluminum,Aluminum profile,Aluminum coil |

| Bending Radius | ≥10mm |

| Material Width | ≤140mm |

| Material Thickness | 0.3mm-1.2mm |

| Machine Power | ≤1500W |

| File Format | DXF, AI, PLT |

| Supporting Software | Leetro software CBS4 |

| Machine Size | 1350mm*750mm*1350mm |

| Machine Weight | 220kg |

| Working Pressure | 0.6Mpa |

| Voltage | 220V50HZ1P |

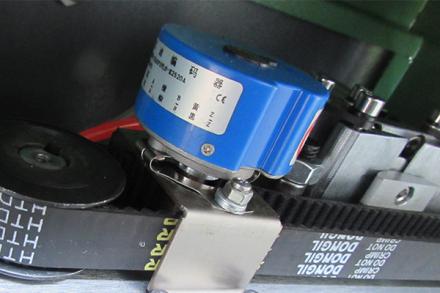

High quality encoder

The high quality encoder used in this machine has high reliability, long life and strong anti-interference performance. With the high-speed precision motor, its high-precision performance makes the feeding control more accurate.

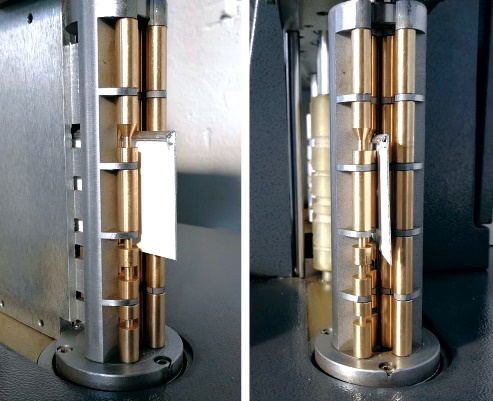

Imported milling cutter

The milling cutter used germany imported alloy-coated tool bit, increase the using lifetime. The tip of the cutter is rounded, ensure the flat sheet bending angle is from -180°to 170°.

Control system

The control card and software is original leetro control system, easy to study and operate, ensure the machine calculating size with zero error. The control card can run stable, with strong anti-interference ability.

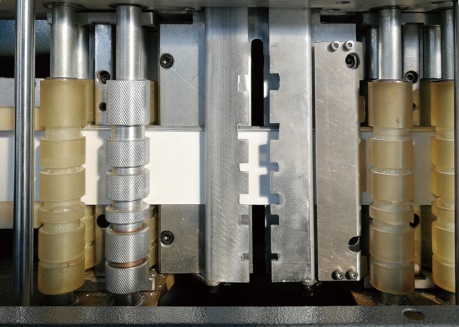

Depth adjusting system

The unique depth adjusting system can automatically adjust the groove depth by modifying the software parameters, and can control the front and back adjustments separately. The motion part adopts screw rod, square rail and slider, which has high precision and good stability.

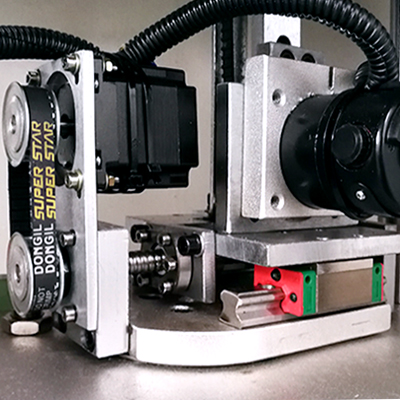

Feeding system

The feeding part is clamped by rubber rollers and driven by gear belt. Fast speed can realize the continuous feeding. It is suitable for flat aluminum, aluminum profile and other different material.

Bending tool

The bending part adopts the working mode of two-axis linkage bending, which is equipped with servo motor and speed reducer. It has fast speed, high precision, no damage to the material surface and small bending interference.